A Leading Global Manufacturer and Supplier of Tungsten Carbide Preforms, Custom Manufactured Tooling, Wear Parts and Specialty Components

John Goodrum and his late partners started the company in 1981. It began in a rented facility and evolved into purchasing a school in Buena Vista, PA. Now, Basic Carbide sells in over 50 countries worldwide, and customers use Basic Carbide material from every corner of the globe.

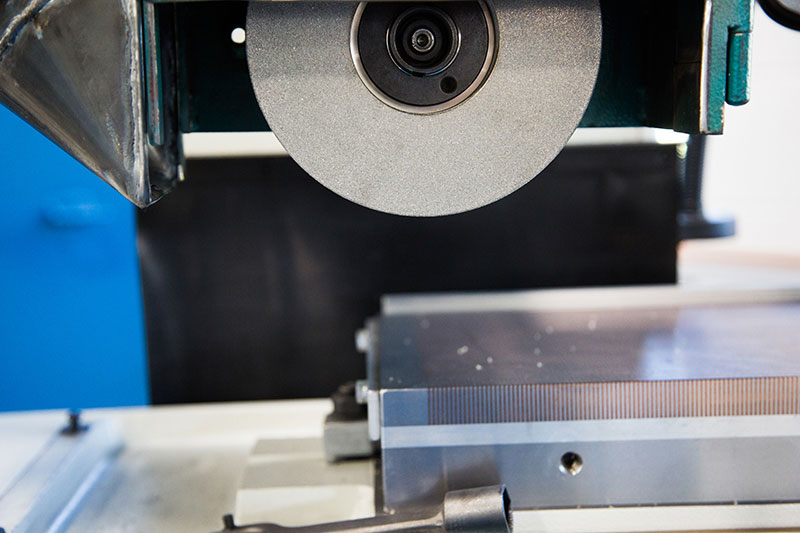

In the early 90s, Basic Carbide expanded quickly, purchasing its second school in Lowber, PA. This facility serves as our nickel binder plant and our corporate headquarters. As the press business grew, Basic Carbide acquired a third facility as its press plant. During the startup years, John and his late partners knew how to hustle and innovate; they built most of their machines to the specifications they needed with a lot of trial and error testing. As Basic Carbide was expanding, we purchased new equipment and engineered these to enhance quality and efficiency.

Nowadays, the family atmosphere is unique to Basic Carbide because John and Donna Goodrum (VP of HR) lead by example. Statistics say that only 10-15% of family businesses make it to the third generation. The Goodrum's and some of their employees have entered the third generation of the family into the workforce. John and Donna Goodrum's family is one of a few; their daughter, Jennifer Sampson (Executive VP), and son, Jonathan Goodrum (President), have grown up and worked at the company for a few decades. Jennifer and Brian Sampson's (QC Manager) son recently began working for the company.

At Basic Carbide, we are committed to setting the standard for quality and reliability in the carbide industry and producing the highest-quality carbide parts available today.

We have an intense, uniform training program for new employees to ensure each job is done right. Our comprehensive maintenance and calibration program lets us stay abreast of issues and maintain high-quality production standards.

Procedures are regularly updated to reflect customers' needs and incorporate new and more efficient ideas into our production process.

Process testing and inspections are an important part of our philosophy; they help us build quality into every product and resolve problems before they occur.

We maintain an extensive data collection system and can track each part through the production process, including lot-specific raw materials, operators, machines, heat, and testing results. At Basic Carbide, we constantly improve today's standards to meet tomorrow's demands.

Superior Quality

Leading Innovation

Quick Turnaround