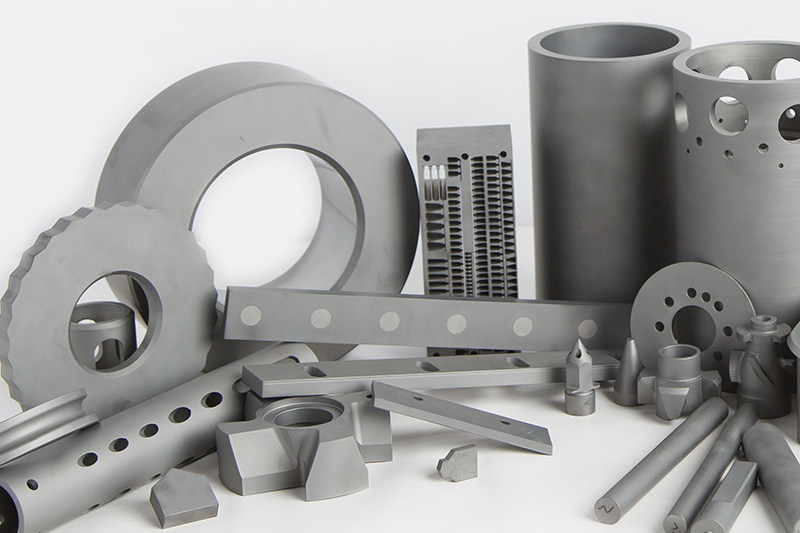

Tungsten Carbide Preforms

Basic Carbide specializes in custom-made tungsten carbide preforms in Cobalt and Nickel grades, including our special cobalt Wire EDM grade.

Superior Quality Tungsten Carbide Preforms

Cobalt Grades: (Need info here)

Nickel Grades: (Need info here)

Custom Grades: We produce custom powder grades to meet your tungsten carbide preform specifications.

Fastest Turnaround: We are a reliable partner in meeting your tungsten carbide preforms needs

No Premium Charges: (Need info here)

Large Tungsten Carbide Preforms: We produce parts up to 20 inches (508 mm) in diameter and up to 44 inches (1117.60 mm) in length.

High Quantities: Our pressing plant allows us to produce high-quantity runs on most parts.

Special Cobalt Wire EDM Grade: (Need info here)

Basic Carbide manufactures a wide variety of tungsten carbide blanks and tungsten carbide preforms for industries worldwide. View our industries served.

Request A Quote

TUNGSTEN CARBIDE BLANKS & TUNGSTEN CARBIDE PREFORMS

At Basic Carbide, we provide the personalized service and technical help you need to ensure your project's success. We produce various sizes and shapes of tungsten carbide products, serving the needs of many industries: Oil & Gas, Automotive, Mining, Manufacturing, Beverage & Aerosol, Housing, Medical, and Recycling.

We can supply our products as tungsten carbide preforms or custom manufacture your tooling, wear parts, or specialty components complete and finished to specifications.

Flexible, fast, and reliable, Basic Carbide is an industry leader in working to meet our customers' specialized needs, including producing custom grades when needed.

Our tungsten carbide preforms product lines include

- Seal Rings

- Saw Blades

- Drill Blanks

- Milling Tool Blanks

- Roto Knives

- Wear Parts

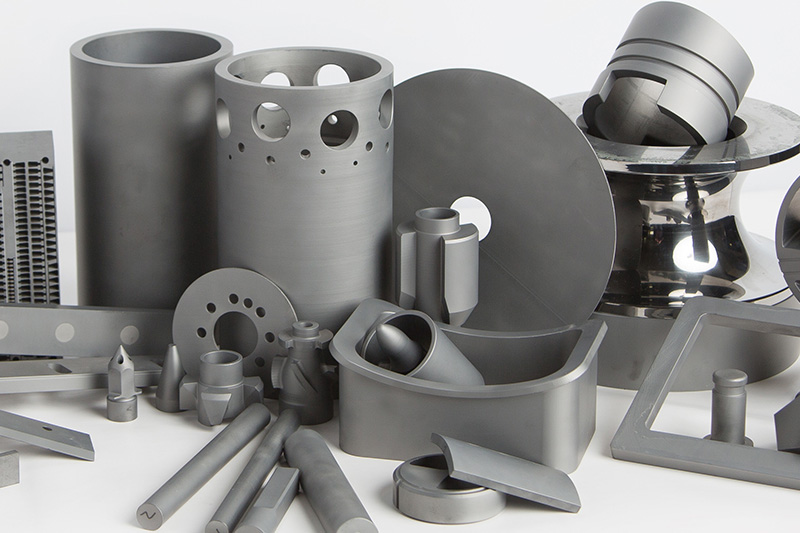

Custom-Made Tungsten Carbide Preforms

Basic Carbide's capabilities include custom-made tungsten carbide preforms and custom carbide grades when required.- Our engineering team creates detailed models for your specified preforms. Once engineered, our computerized models help maintain product consistency and allow for fast turnaround on repeat orders.

- Our blending and testing services take raw materials and create high-quality carbide grades for state-of-the-art tooling and industrial production.

- Pressing, shaping, and sintering produces very hard cemented carbide blanks and preforms ready to be worked into finished tools.

Our quality assurance protocols include a visual check and dimensional and metallurgical inspection before packaging and shipping.

LARGE PREFORMS

Basic Carbide can produce tungsten carbide preforms of approximately 20 inches (508 mm) in diameter and up to 44 inches (1117.60 mm) in length.

Our unique hydraulic press plant allows us to produce high-volume runs while being globally competitive.

Exact limits depend on the configuration of the parts.

HIGH QUANTITIES

Basic Carbide produces high-quantity runs for select parts. The configuration and size of the part determine its suitability for mechanical pressing.

Tooling charges may apply if specialized tooling is necessary.

SPECIAL REQUESTS AND PROCESSING

We often perform special processing, such as installing soft plugs for tapping, cobalt-treating surfaces to facilitate brazing, special sintering for Wire E.D.M. processing, and sinter-H.I.P. processing.

- Installing soft plugs for tapping

- Cobalt-treating surfaces to facilitate brazing

- Special sintering for Wire E.D.M. processing

- Sinter-H.I.P. processing

CUSTOM CARBIDE GRADES

When needed, Basic Carbide produces custom grades of carbide for interested customers.

Custom blending requires a minimum quantity or total weight produced. Customers may also inquire about leftover custom-grade lots.

RUSH ORDERS

In addition to our capabilities, we provide fast quotes and deliver a quick turnaround of parts for urgent orders. We ensure quality assurance in every situation.

We can work with our customers to better serve their needs. For more information on any of our capabilities, please get in touch with our Sales Department sales@basiccarbide.com or use our contact form.

With fast quoting and rush turnaround in emergencies, Basic Carbide Corporation is a reliable partner in meeting your carbide tooling needs. To learn more, call us at 1-800-426-4291 or use our contact form today.

Custom Made Tungsten Carbide Preforms

- Seal Rings

- Can Tooling

- Forming Rolls

- Powder Compacting

- Stamping

- Saw Blades

- Dies

- Cutters

- Drill Blanks

- Bushings

- Rods

- Oil Field

- Slitter Knives

- Bed Knives

- Rotor Knives

- Wear Parts

- Punches

- Automotive

- Milling Tool Blanks

- Balls

- Seats

- Nozzles

- Plates

Carbide Grade Chart

Basic Carbide offers many Tungsten Carbide, Nickel and Submicron Grades to meet your specifications.

Quality Assurance Program

We are committed in providing the highest-quality tooling, wear parts and specialty component products and services to our customers. We have established an advanced inspection, equipment and documented Quality Assurance Program to ensure we meet and exceed our clients expectations.